StOPHIT Cell

At LEAD, we design scientific instrumentation to develop and test novel laser-based measurement techniques. One example is the St. Olaf Pulsed Hypersonic Improved Test (StOPHIT) cell, a chamber designed to replicate the conditions encountered in cold high-speed wind tunnel facilities. This instrument is capable of generating pulsed gas flows at Mach numbers between 2.9 and 6.2, and temperatures as low as 34 Kelvin.

The nozzle assembly

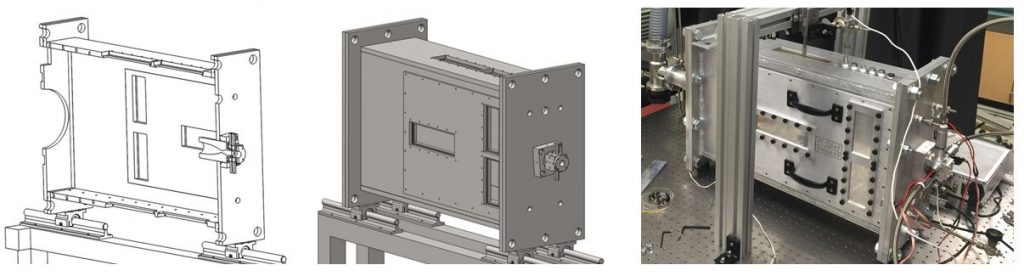

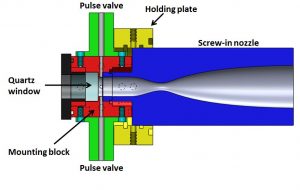

The central component of the StOPHIT cell is the nozzle assembly. It consists of an aluminum block fitted with multiple pulsed valves and a screw-in aluminum converging-diverging nozzle.

Recent improvements of this assembly includes the addition of 3D-printed nozzles and high-performance fuel injectors for pulsed gas delivery.

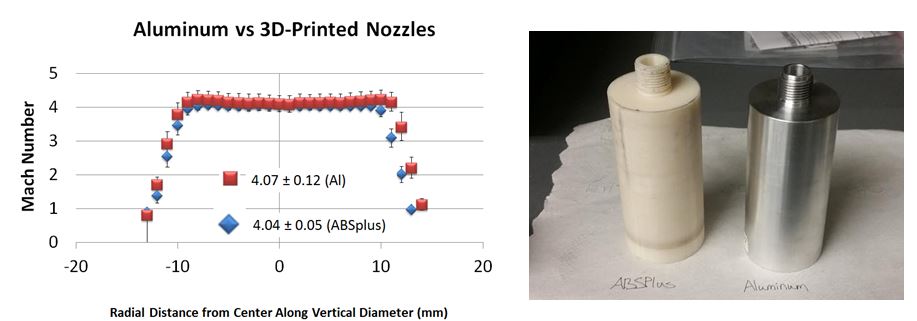

Flow quality

We have characterized the flows generated by this instrument using fast response pressure sensors. During the uniform flow time interval within each pulse, the pressure at the nozzle exit varies by less than 1%, corresponding to fluctuations in the exit velocity and temperature within 1%, for Mach numbers between 2.8 and 6.2. These conditions offer flows of sufficient quality for quantitative measurements such as low-temperature kinetics, energy transfer, and development and validation of laser diagnostics under repeatable and spatially uniform conditions. We have observed identical flow quality using CNC-machined aluminum nozzles and 3D-printed nozzles.